ADVICES AND TIPS FOR CUSTOMERS

Drilling:

Sometimes it is necessary to drill a hole down additionally at the place of destination of the product. So, is it possible to drill into plexiglas and polycarbonate in “domestic” conditions? Yes, of course.

For polycarbonate, there is a possibility to use any kind of drill, but the situation about plexiglas is a little more complicated.

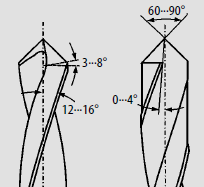

Suitable drills for plexiglas:

|

|

When drilling, make sure:

- Cutting speed is correct, the right move can be recognized when a shaving is smooth and continuously coiled

- When fixing, shortly before breaking through, slow down the move

- For large diameters it is a good to predrill the centre by a smaller, suitable drill

- To create a thread are used common screw taps

Cleaning:

From time to time, it is necessary to clean the plexiglas components. Dusty parts should be washed with water and soft cloth or flannel (we have good experience with Swedish dishtowels). Never wipe it off to dryness.

Products that are made of plexiglas, polycarbonate or PETG must not be cleaned with alcohol-based agents!

Bending:

Plexiglas and polycarbonate can be slightly formed cold and manually (at the material thickness of 2-4 mm) into e.g. a frame, which will keep the bending of the material in the shape for all the time. Various shaping of thicker material into arcs or other shapes that are supposed to have the desired shape forever, is carried out by usage of a machine, see a chapter Bending (upper menu).

Absolutely not recommended to help yourself by, for example, a heat gun or open flame. Although the material could be able to bend, after cooling an effect called “Internal stress” may cause destruction of the material.

Conclusion:

Plexiglas is a brittle material, which can be shattered and handling with it should be carried out more carefully than with other materials.